LEARN MORE ABOUT OUR MANUFACTURING PROCESS.

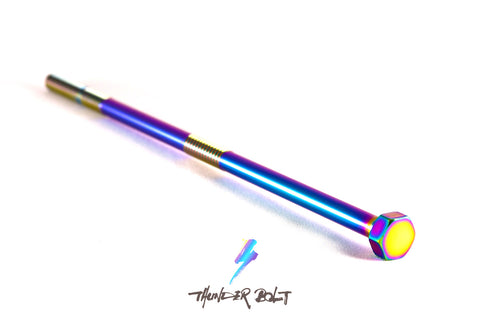

Thunder Bolt Titanium has extensive experience and skills of fastener products since its establishment. Also, we have the experience of producing OEM parts for a wide range of applications.We are delivering high quality titanium bolts, nuts, washers and titanium fasteners all over the world according to customer's request.

Boost creativity and focus.

You should know that a completely different product is born from the same drawing.

The beauty of detail enhances creativity.

We are aerospace quality.

All our titanium fasteners are manufactured with aerospace quality titanium alloy Ti 6AL-4V (ASTM B348 Gr 5 and TAB 6400). And we are doing high quality control to make the fasteners.

We are called the "TAKUMI".

Our craftsmen have a delicate technique and feeling. In order to carry out a very beautiful finishing,They re examine the processing for every small details. Because this is the Japanese craftmanship

Even without drawing is not a problem.

You want to produce, you need a drawing. But No problem. We can make it with you.

Or, You are welcome if you can prepare drawings. You can order over 300pcs of titanium fasteners of the same kind at once, we will offer very good price!

First,Please contact to us!!

Production Case

Case 1 : Production for Automobile Engine.

M10 L273mm and L263.5mm Machined from forged titanium.

It was a production request from Finland.

Case 2 : Production for Reinforcing bolt for Racing Car

M12 and M14 Body is forged and Rolling Thread.

It was a production request from TOYOTA dealer in Japan.

Case 3 : Production for Stem bolt

M7 L28mm 12points inner socket. It's Titanium bolt for luxury fashion Lims.

It was a production request from Japan's wheel manufacturer with very high inspection standards.